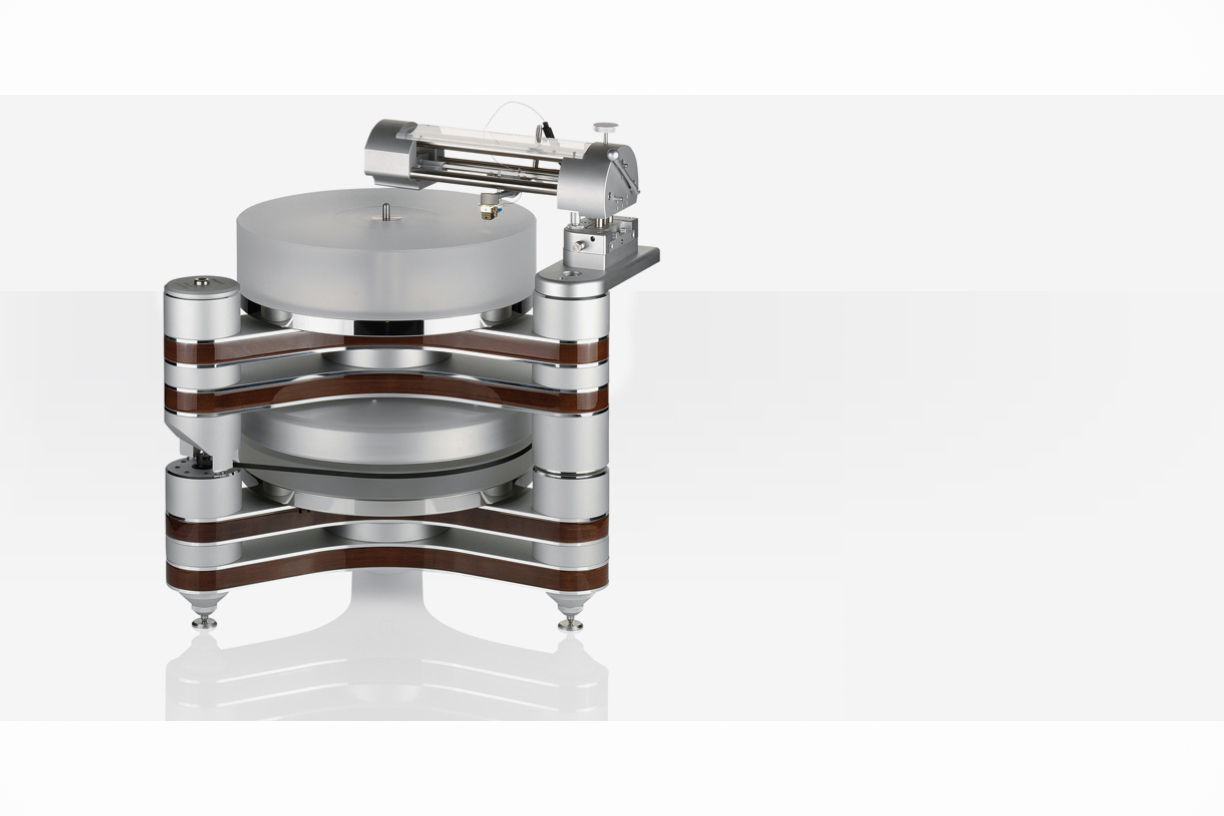

Clearaudio Master Innovation

18699.00€

Clearaudio LP mängija

Hi-Fi News

Audiophile

Toode on saadaval tellimisega

Tehnilised andmed

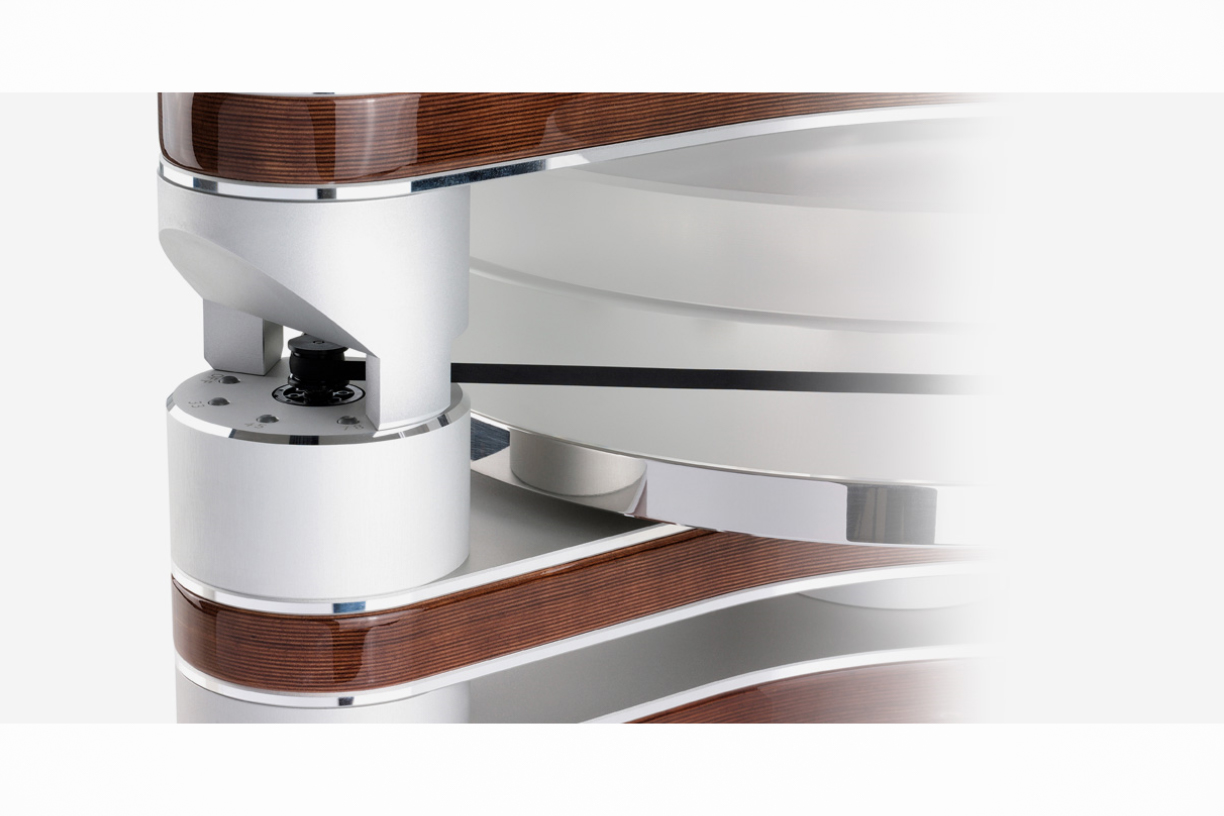

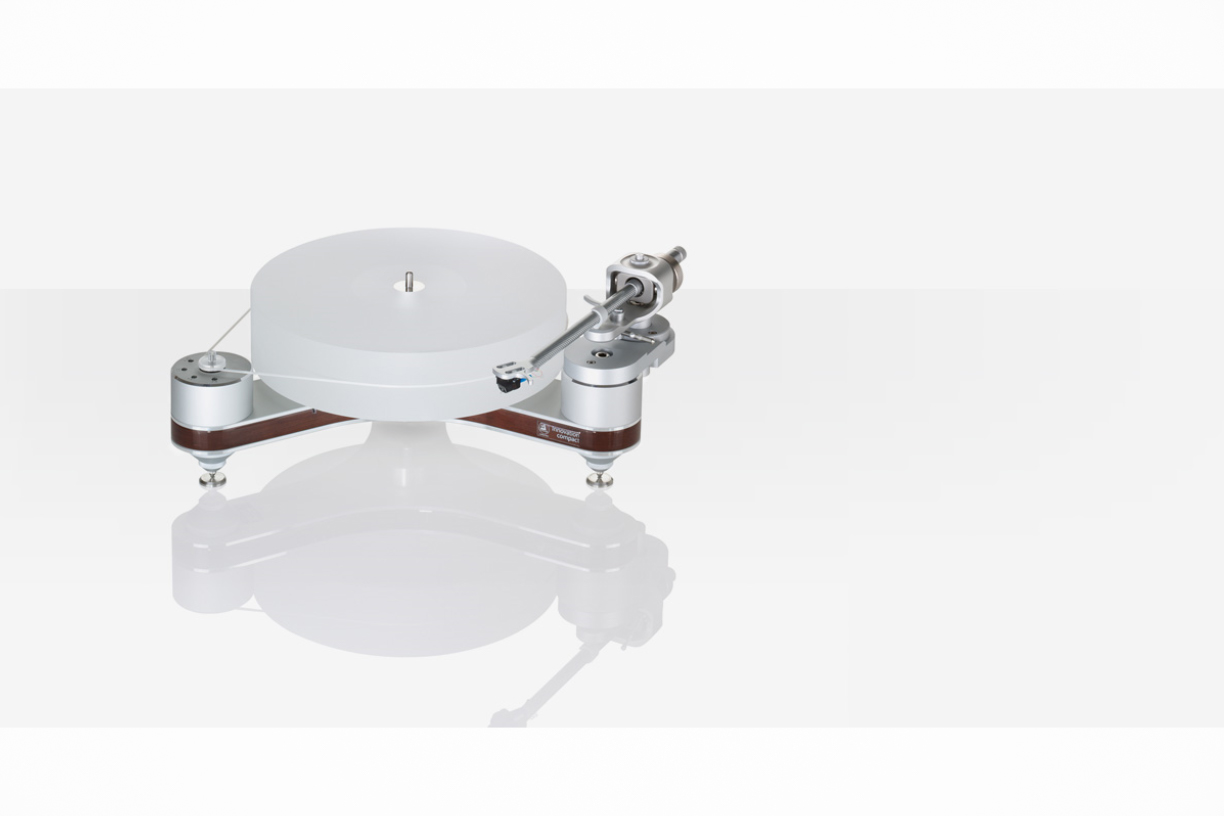

| CONSTRUCTION DETAILS | Resonance optimised chassis’s shape, belt driven with optical, full automatic speed control, speed transmission via contact-free magnetic coupling |

| SPEED RANGES | 33 ⅓, 45 and 78 rpm |

| DRIVE UNIT | Decoupled DC motor in a massive metal-housing. Motor can be used from 100 V to 240 V (50/60 Hz) |

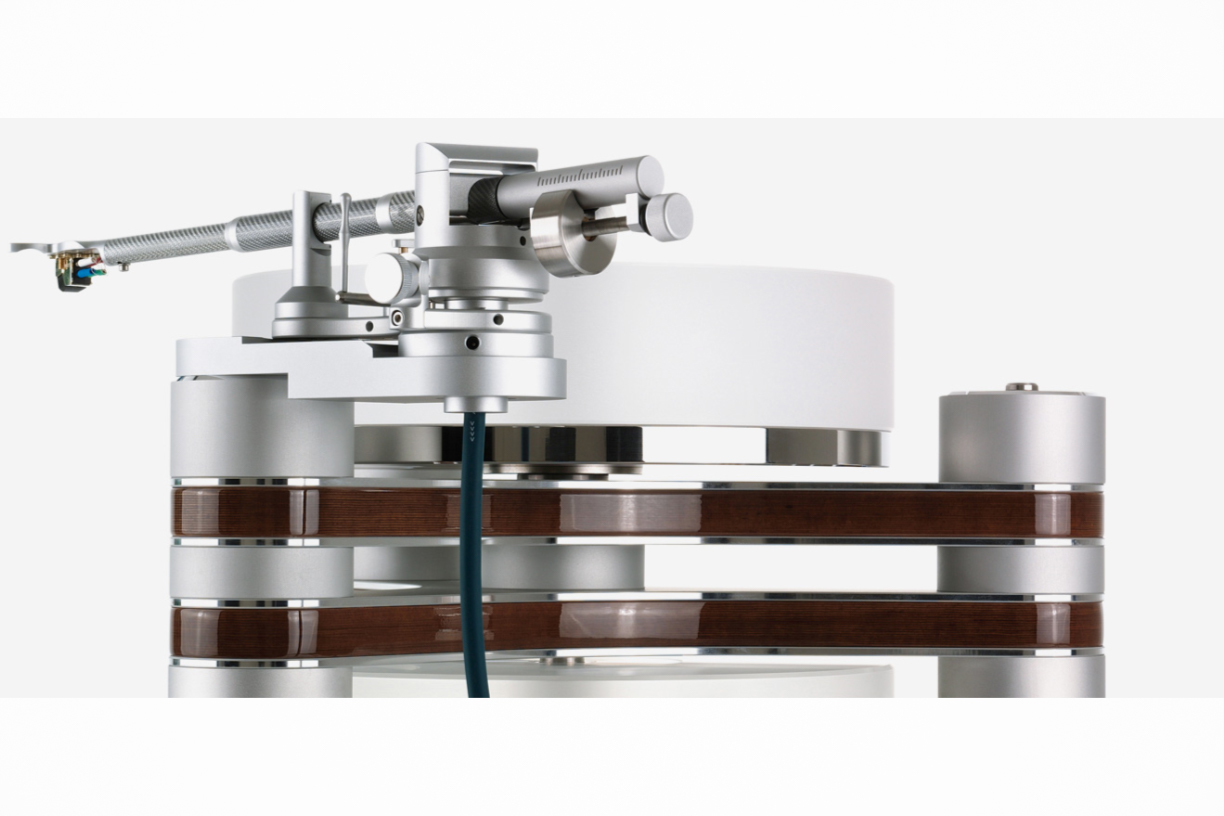

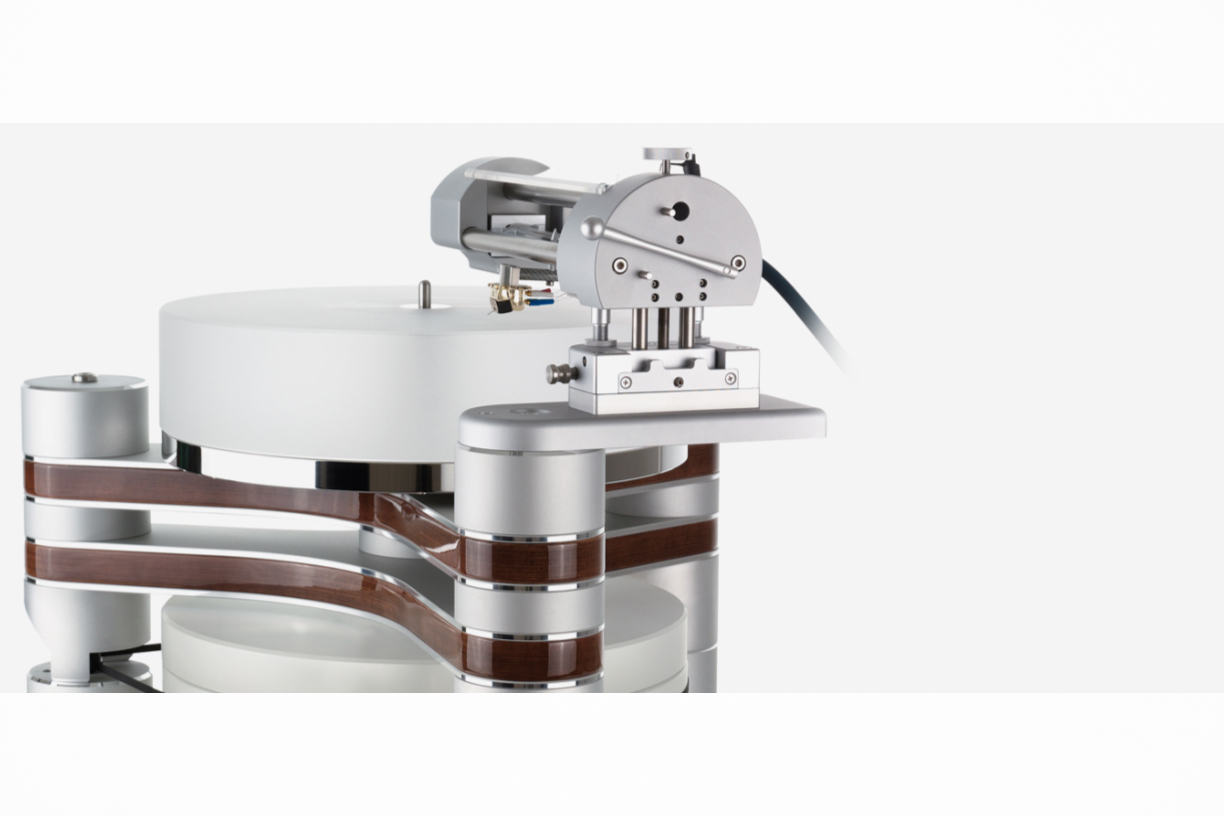

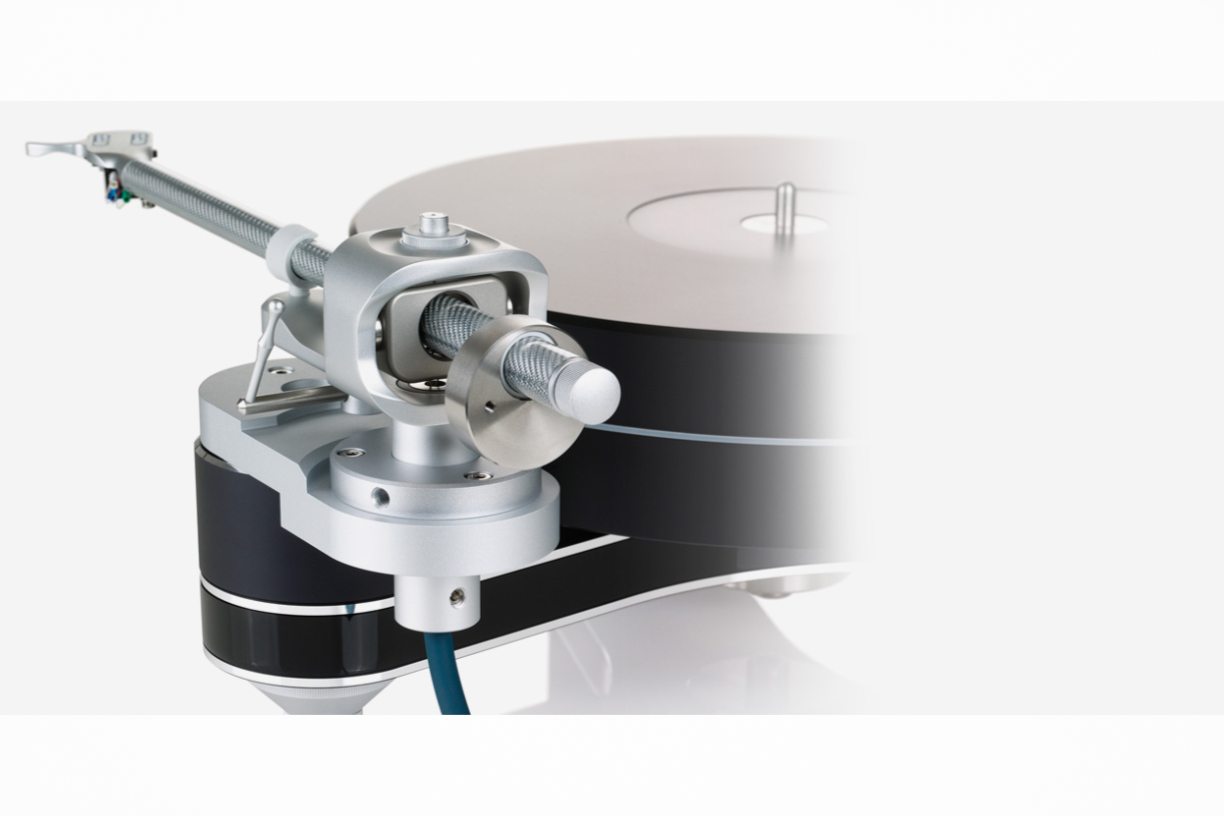

| BEARING | Drive bearing: Inverted and polished bearing shaft, polished sinter bronze insert and ceramic ball Platter bearing: Magnet bearing technology, sharpened and polished bearing shaft |

| PLATTER | VA stainless steel sub-platter, Delrin or acrylic GS-PMMA platter, precision CNC machined surface |

| SPEED ACCURACY (MEASURED) | less than ± 0.05 % |

| DEVIANCE OF THE SET VALUE | ± 0.01 % |

| POWER CONSUMPTION | Max. consumption: 9.5 Watt Consumption in operation: 4.1 Watt Standby mode: 2.4 Watt Off mode: 0.0 Watt |

| TOTAL WEIGHT | Approx. 60 kg (without tonearm and power supply) |

| DIMENSIONS (W/D/H in inches) | Approx. 16.85 x 15.35 x 15.59 (without tonearm) |

| DIMENSIONS (W/D/H in mm) | Approx. 428 x 390 x 396 (without tonearm) |

The 70mm-thick, dynamically balanced platter made of resonance damping plastic with a 15mm-thick precision-machined stainless steel sub platter delivers the highest mechanical standards. The Master Innovation doubles the inertia of the Innovation.

Incredible rotational speed stability is achieved thanks to the combination of the patented Clearaudio ceramic magnetic bearing (CMB) supplemented by an additional flywheel and a high torque DC motor. An infrared sensor sends signals to an optical speed control mechanism to consistently maintain the perfect speed, while non-contact magnetic decoupling of the drive prevents any vibration or noise from the motor system from reaching the main turntable. Consequently, speed variations are eradicated and perfect pitch is obtained. The Master Innovation provides the ability to mount up to three tonearms. Existing Innovation owners have the option to upgrade to Master Innovation level.

Seotud tooted

Clearaudio